WeChat 15510333008

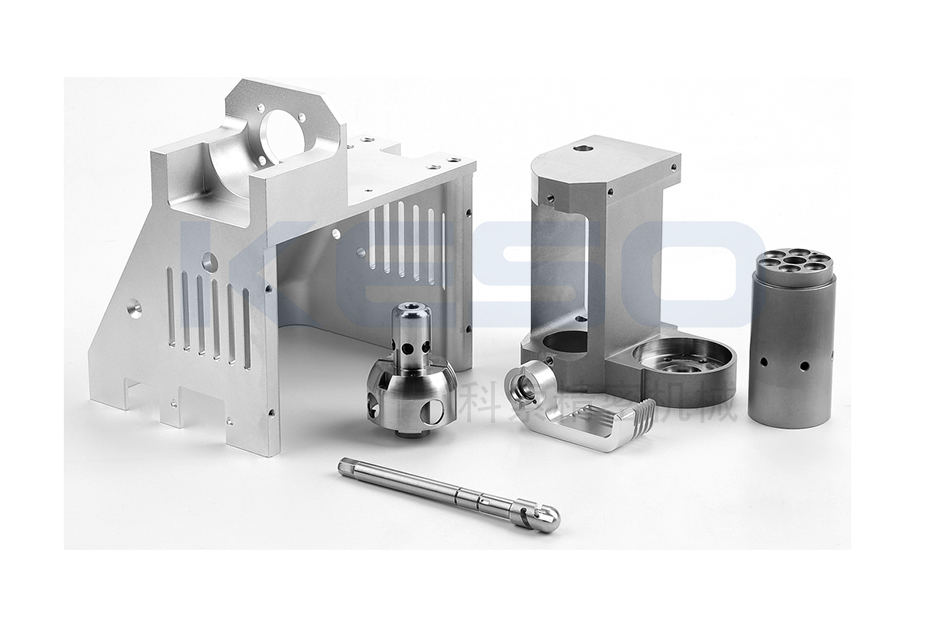

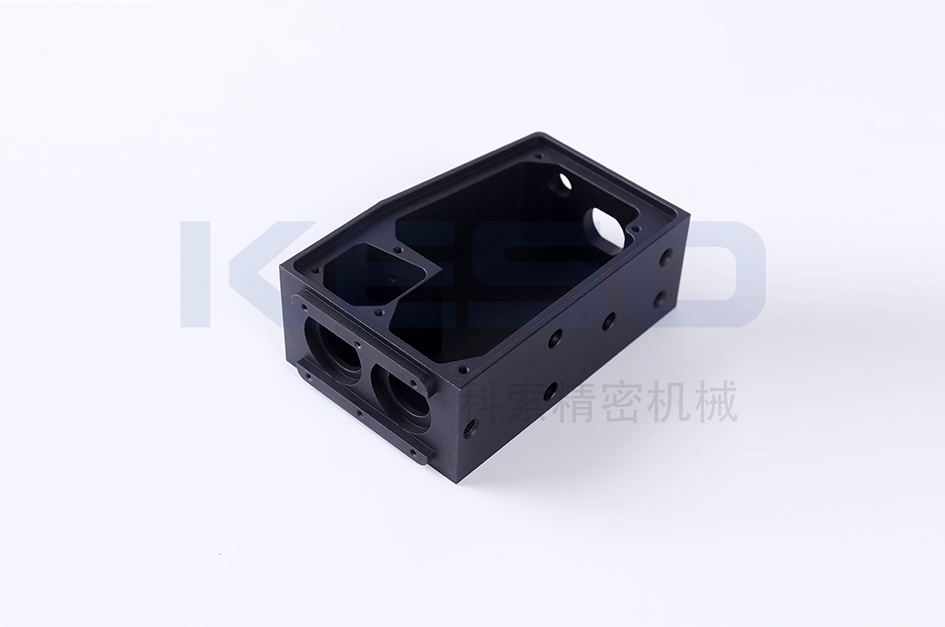

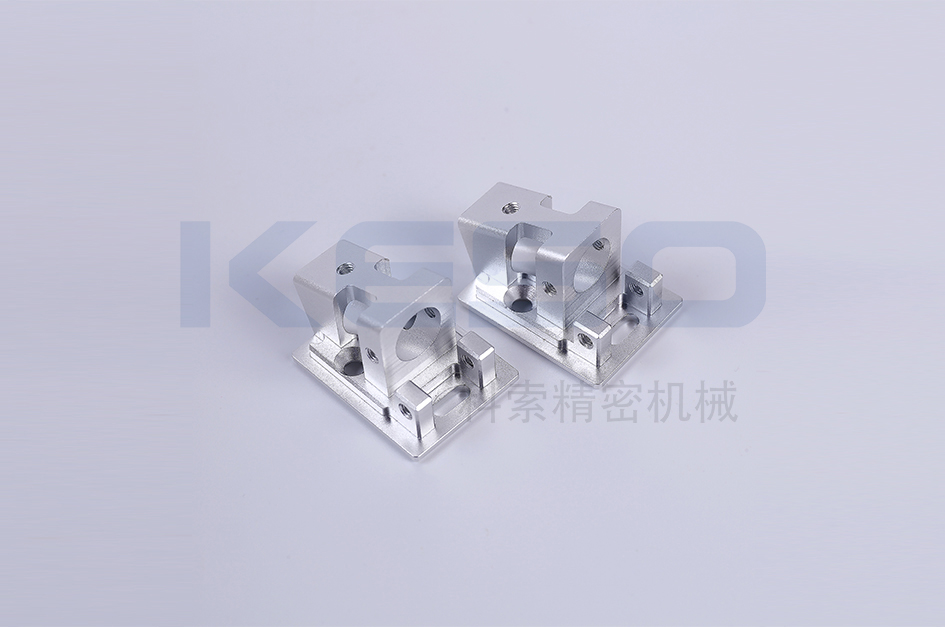

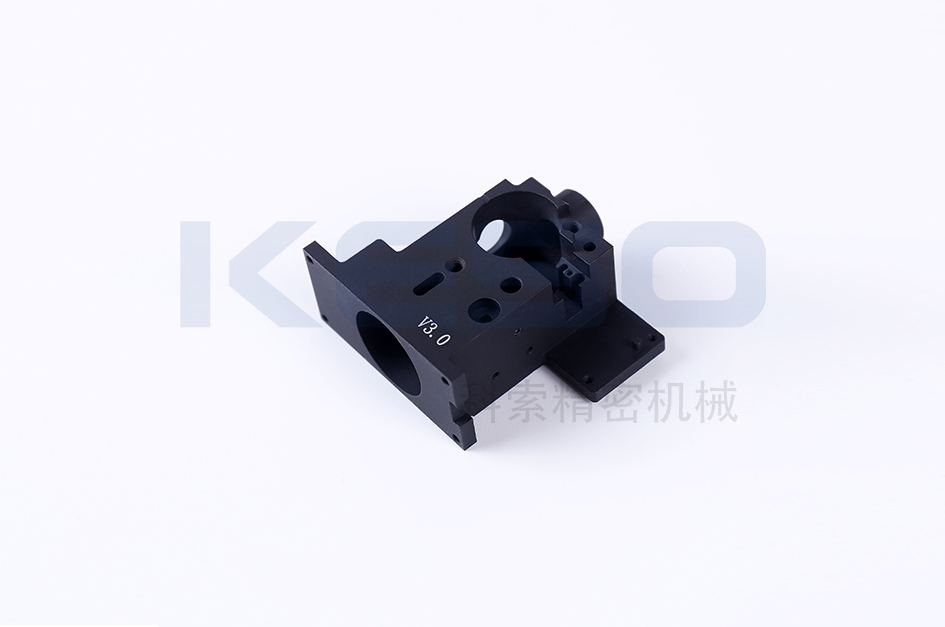

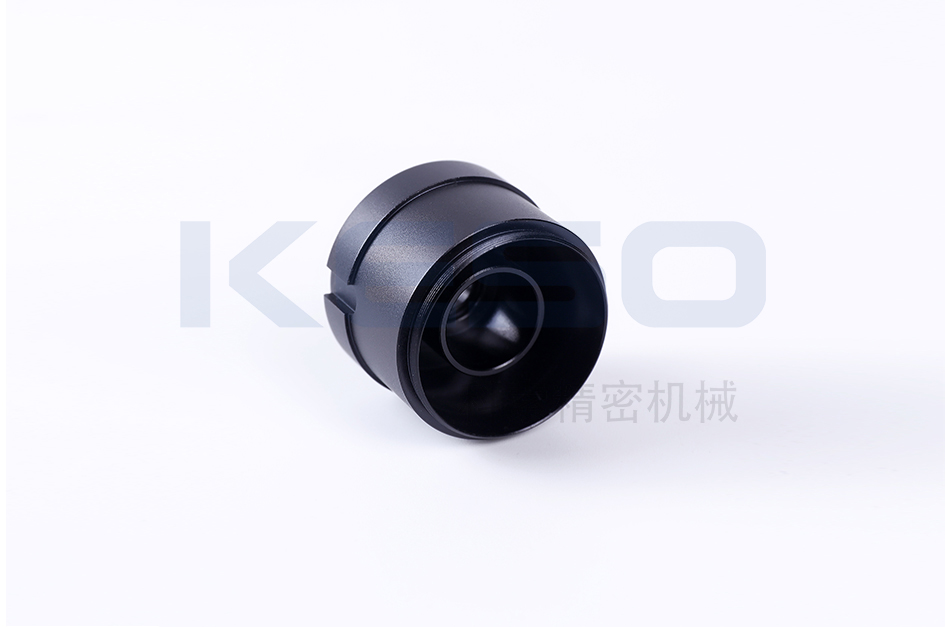

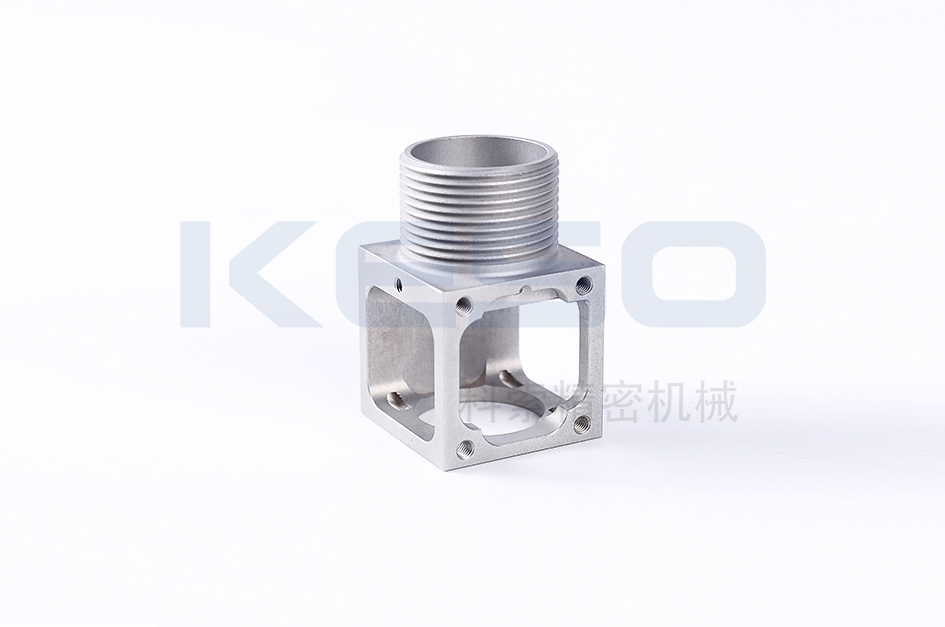

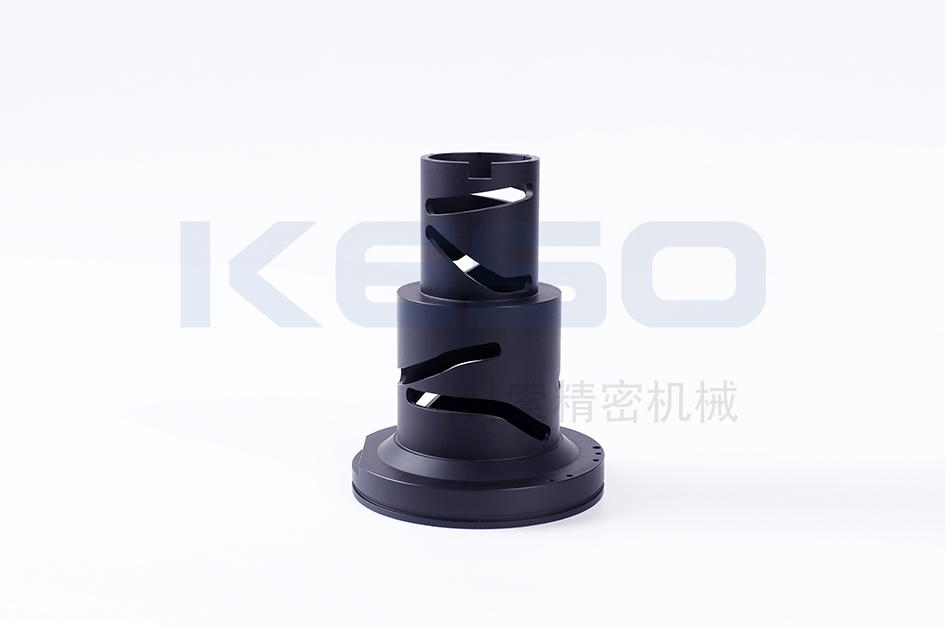

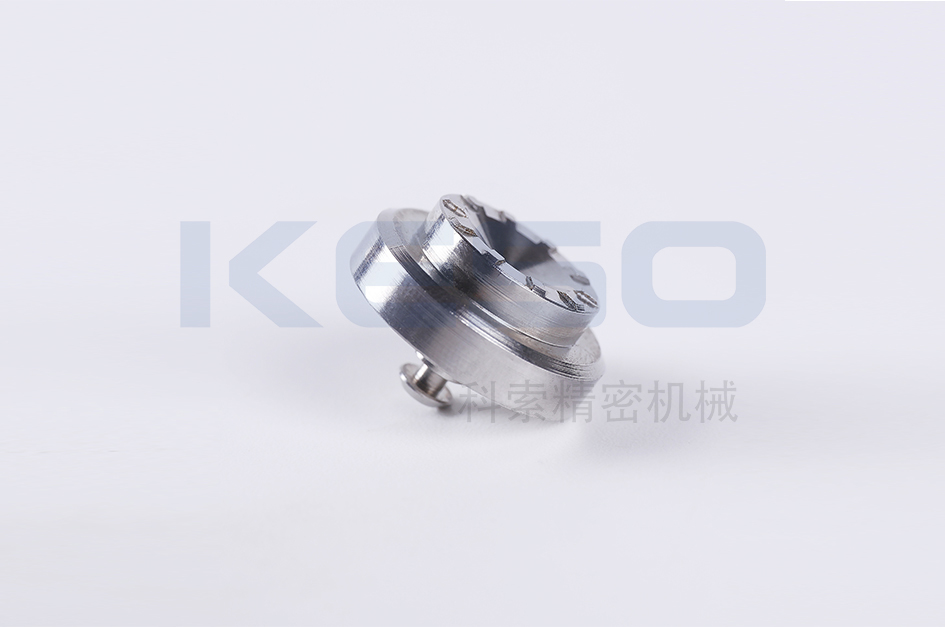

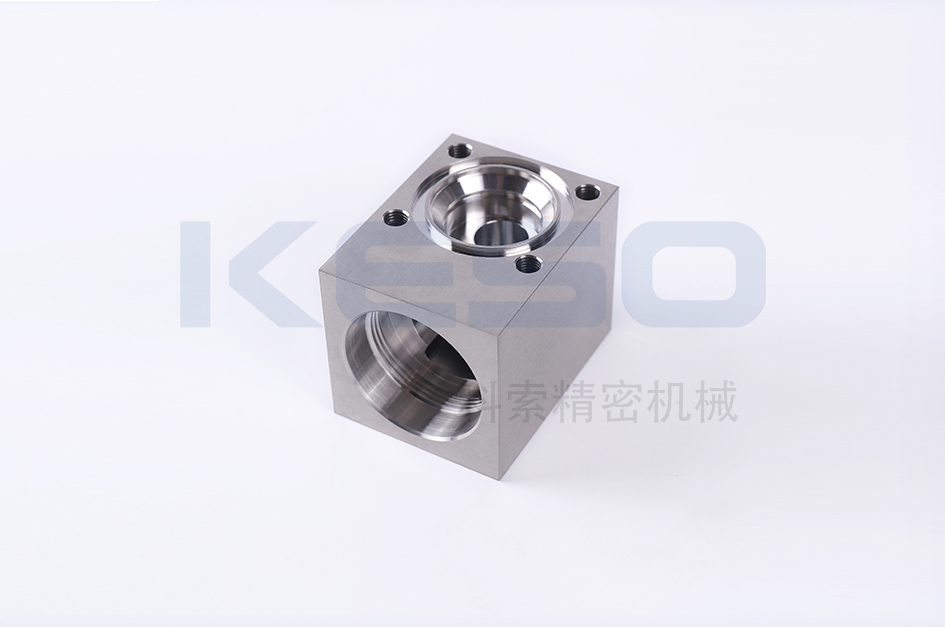

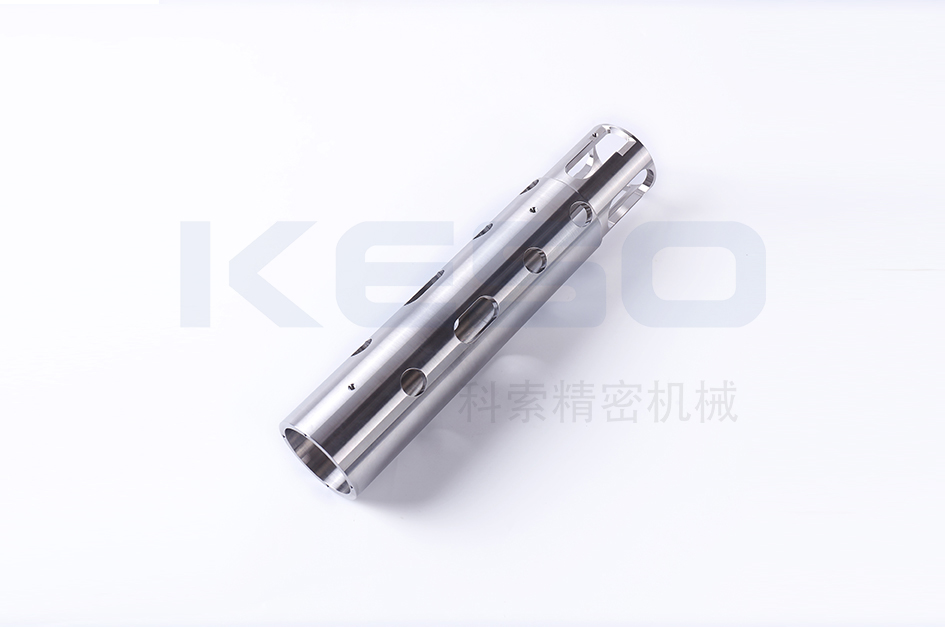

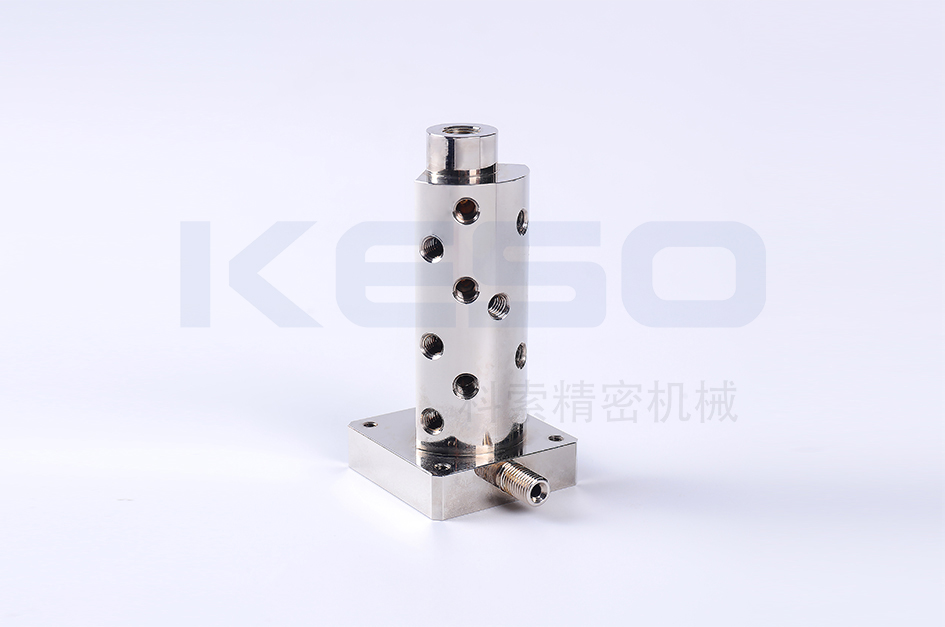

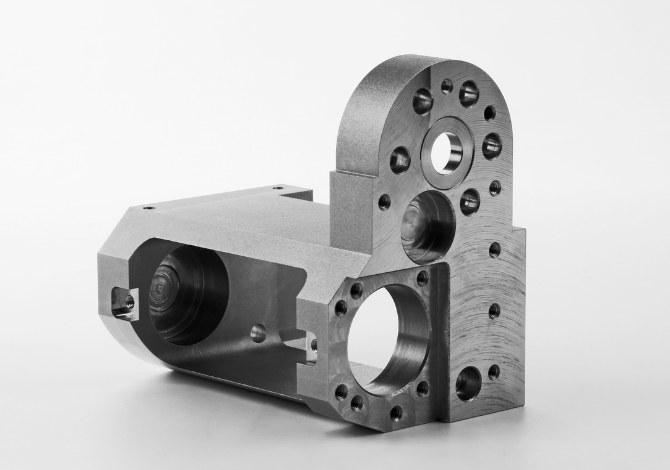

Supply high-precision core

components for enterprises

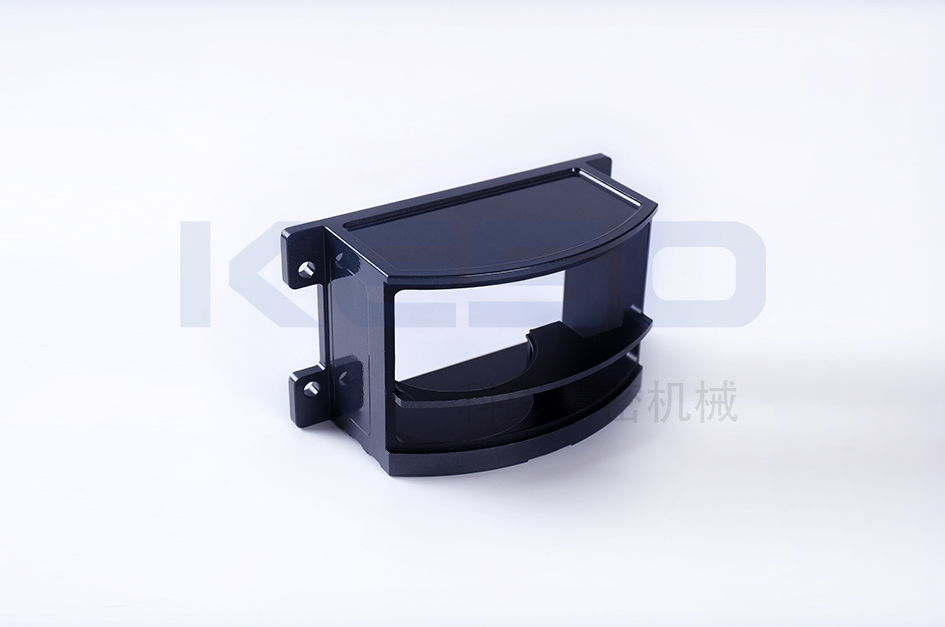

Highly competitive prototype manufacturing capabilities

11 five-axis high-speed precision machining centers

11 years of experience in prototyping precision structural parts

12 four-axis machining centers

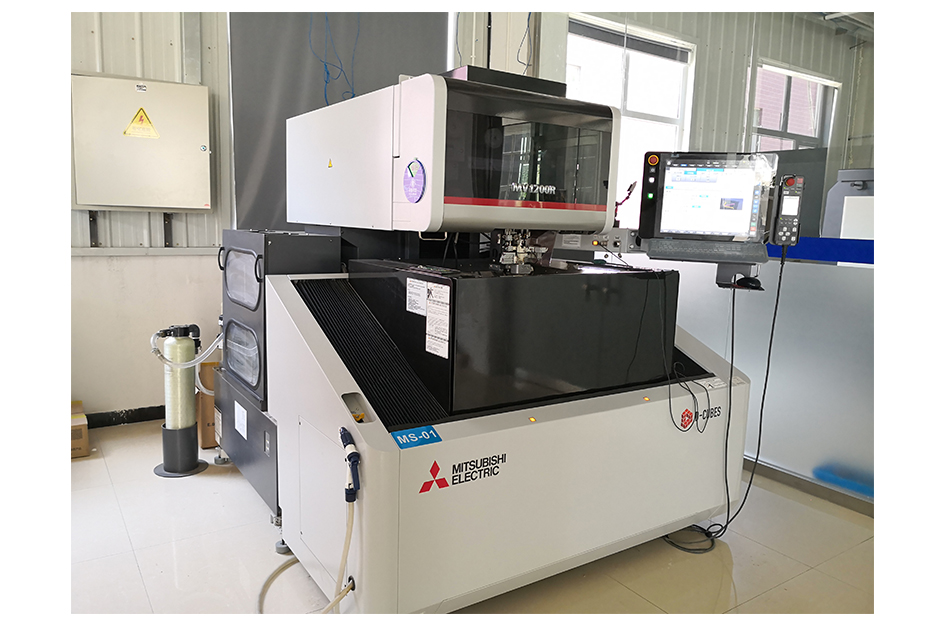

CNC grinding, slow wire, spark machine, turning and milling composite, from prototype to mass production, with full sequence processing capabilities

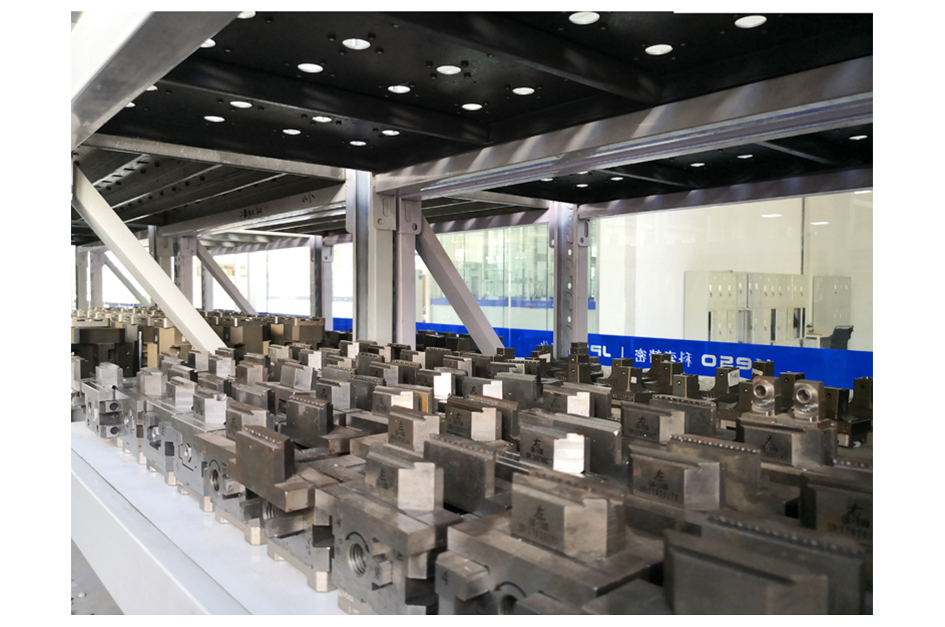

Sound version management and stable pricing capabilities

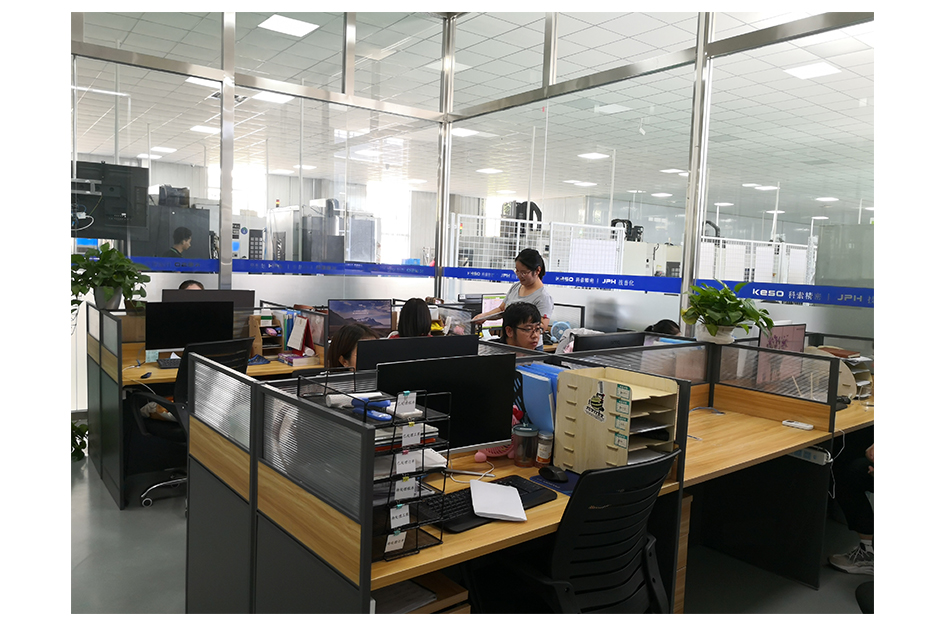

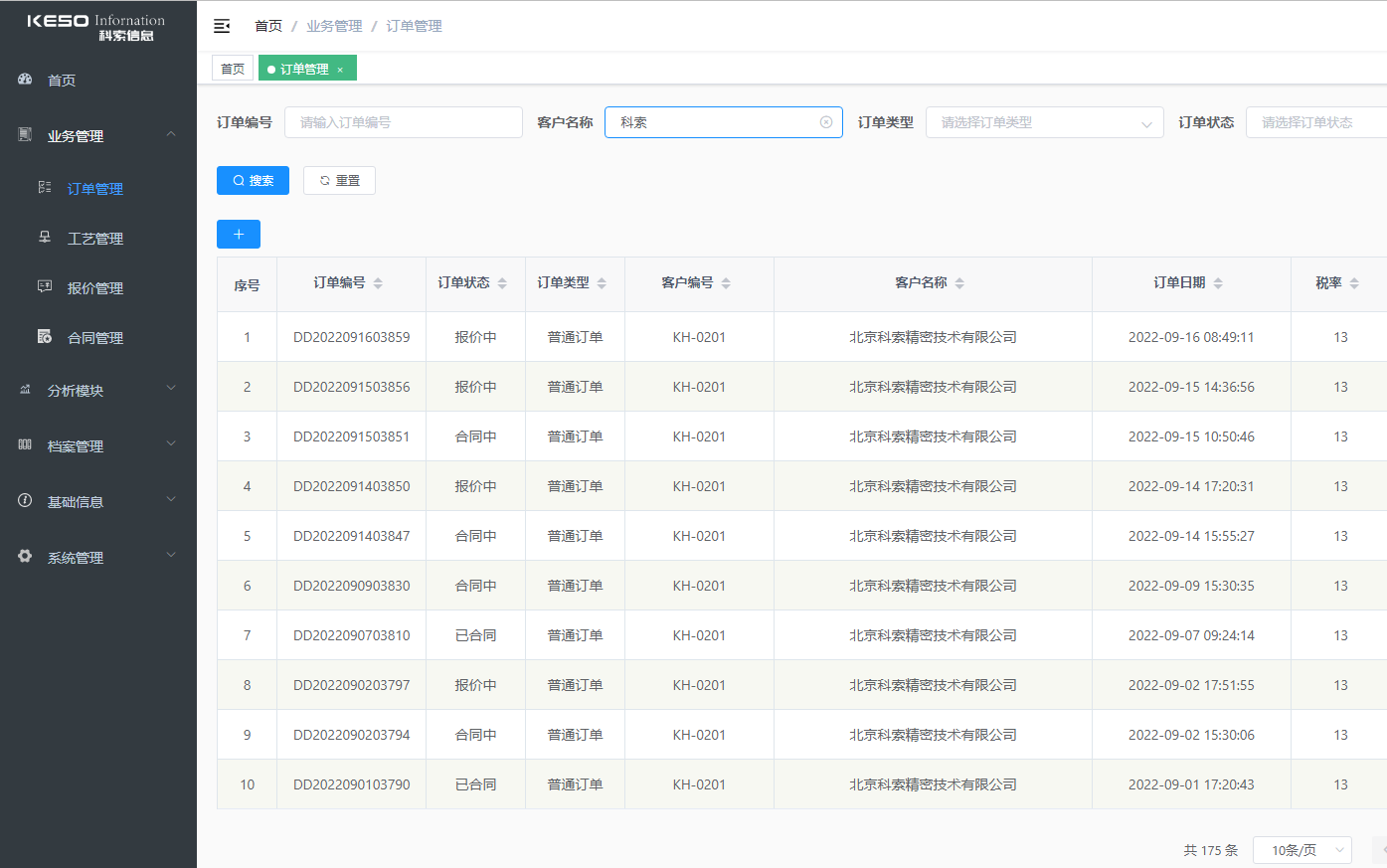

KESO's independently developed process management system

Get the price in as little as 10 minutes, share the process with customers, and check the price more transparently.Powerful version management function, so that the variety of parts can be diversified, can calmly cope with the system can automatically identify similar materials and re-input materials, similar materials within the set to use a unified price, provincial approval.

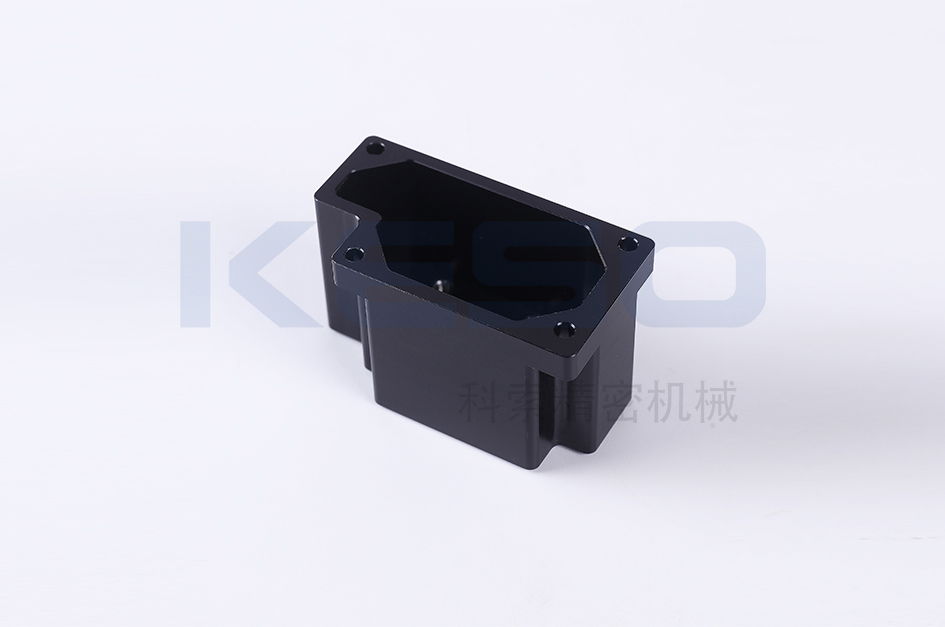

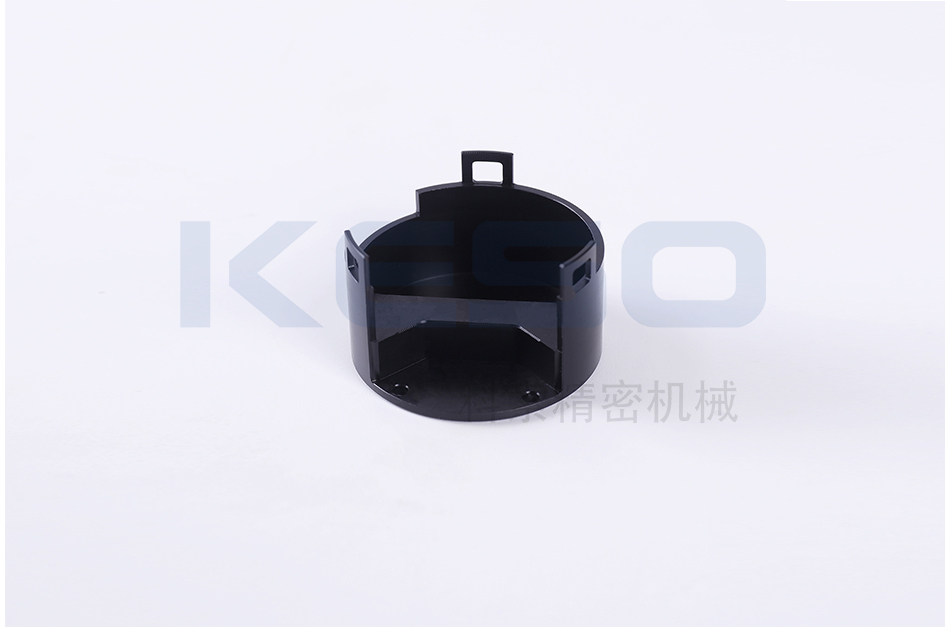

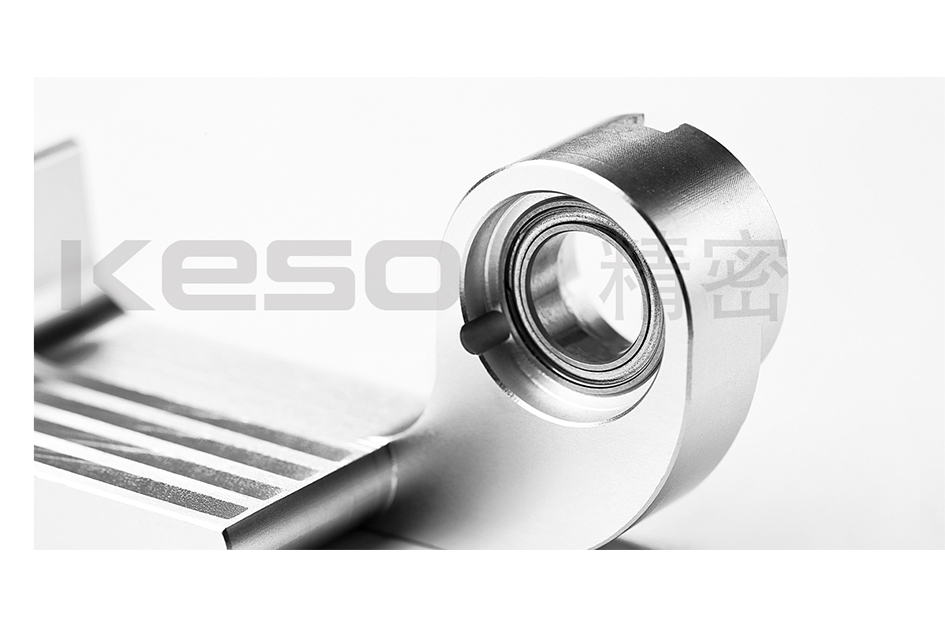

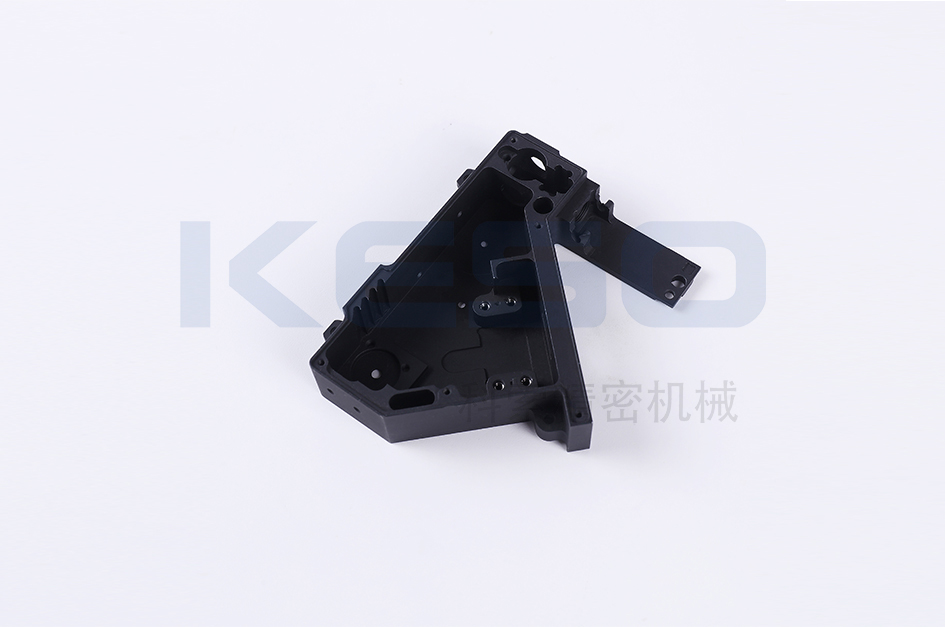

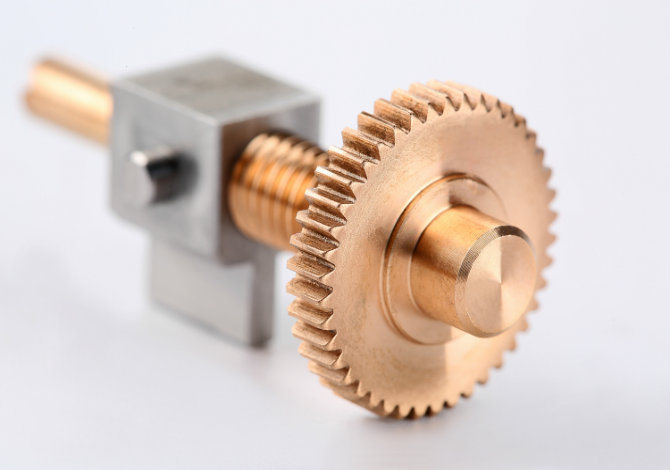

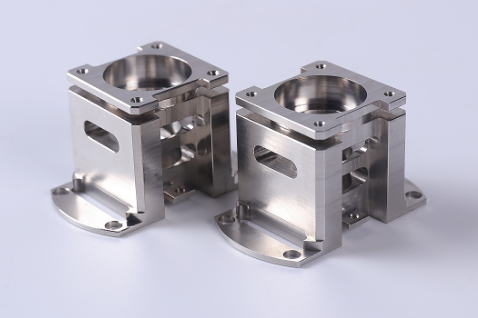

Stronger process and hardware advantages

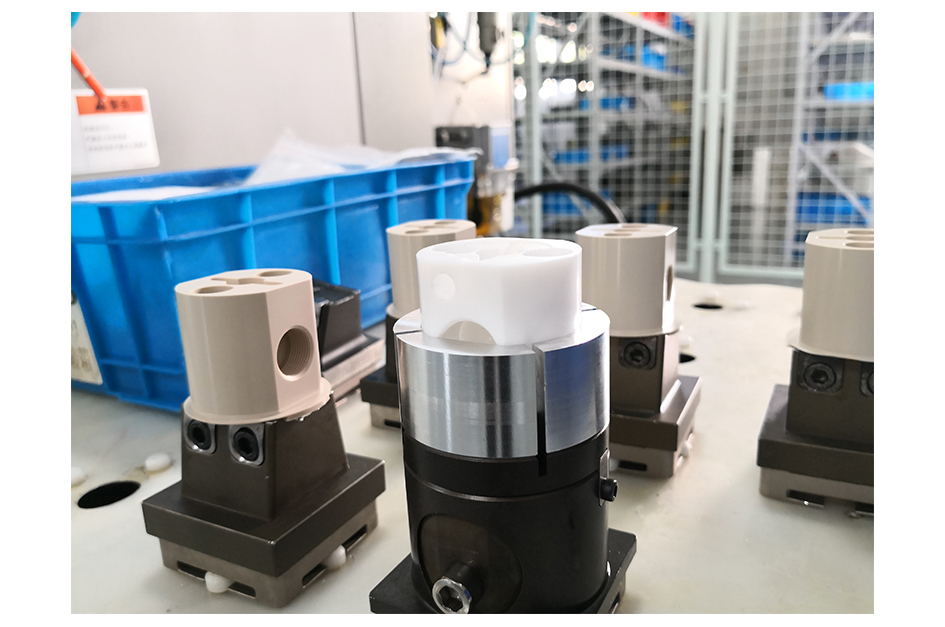

Whether it is trial production or mass production, we have complete processing standards and feature processing specifications, and the production standards database has been accumulated for 11 years and has been continuous. Self-developed five-axis CNC automatic production unit stable processing accuracy :0.002mm, it can automatically load and unload materials and tools, online measurement of the processed material accuracy and tool anomaly management. With the interchangeable clamping and positioning system of KESO throughout the workshop, the positioning error caused by repeated clamping can be solved, and the production workshop can realize the conventional precision machining of 0.005mm and the high-precision machining of 0.002mm.

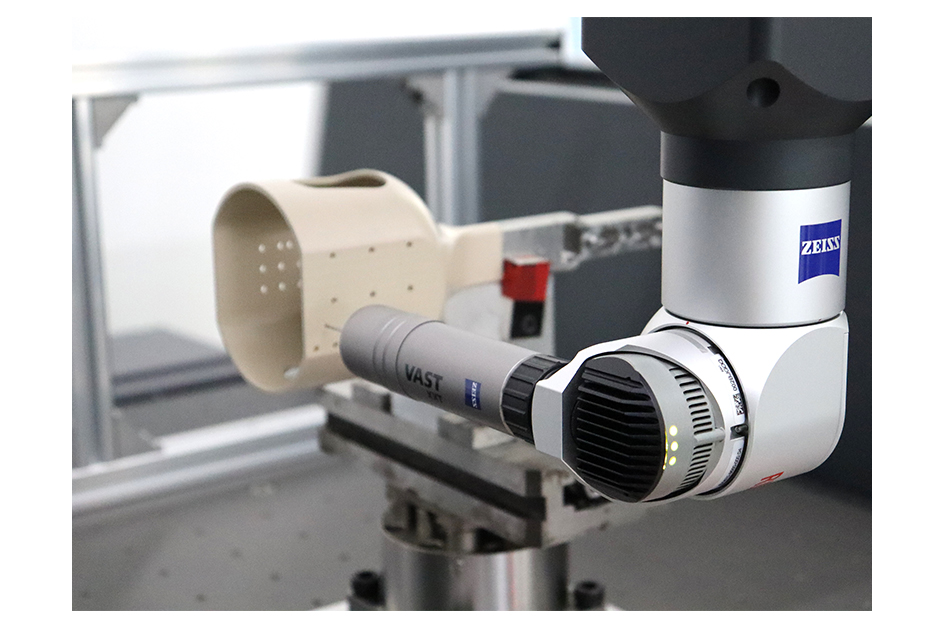

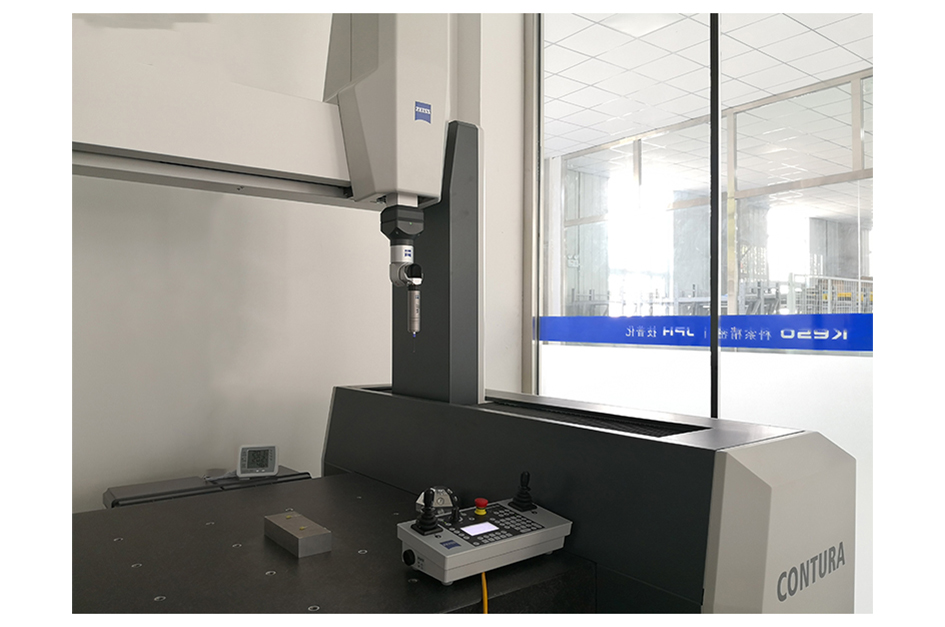

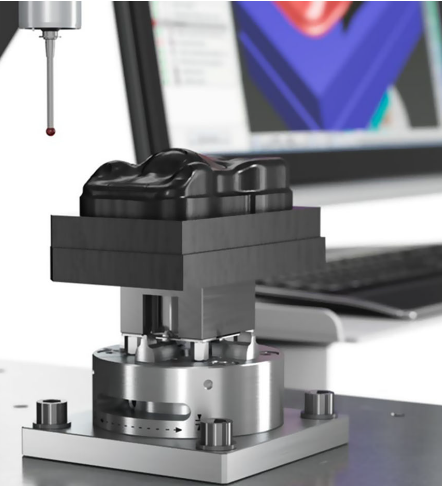

High precision measurement equipment

Zeiss five axes three coordinates

COM 3D measurement

The German GOM automatic measurement technology was introduced, and a complete application scheme was developed for the second time. After 3D model modeling, reverse comparison was made, and efficient measurement scenarios were available. High-precision measurement using Zeiss five-axis three-coordinate, measuring calibration limit error of 1.2um.

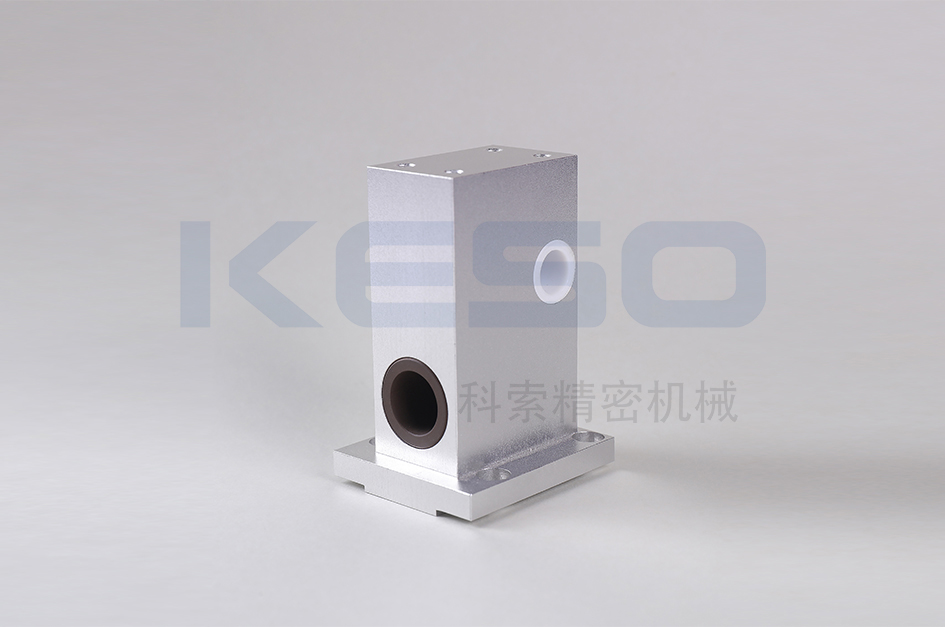

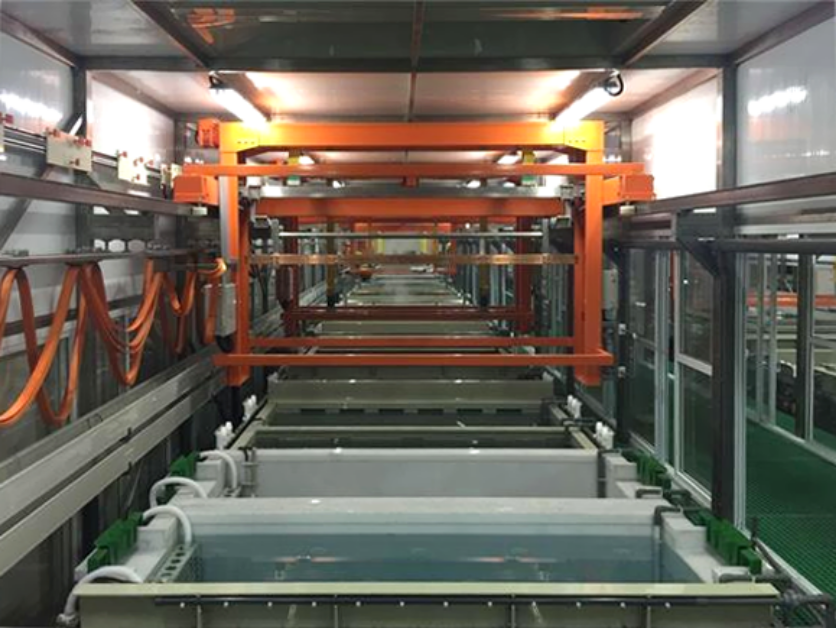

A complete downstream industry chain that is autonomous (controlled) and controllable

Autonomous and controllable complete downstream industry chain to meet the dimensional tolerance control after surface treatment.

Quality System Management Qualification

Medical machinery production q

Weapon and equipment quality s

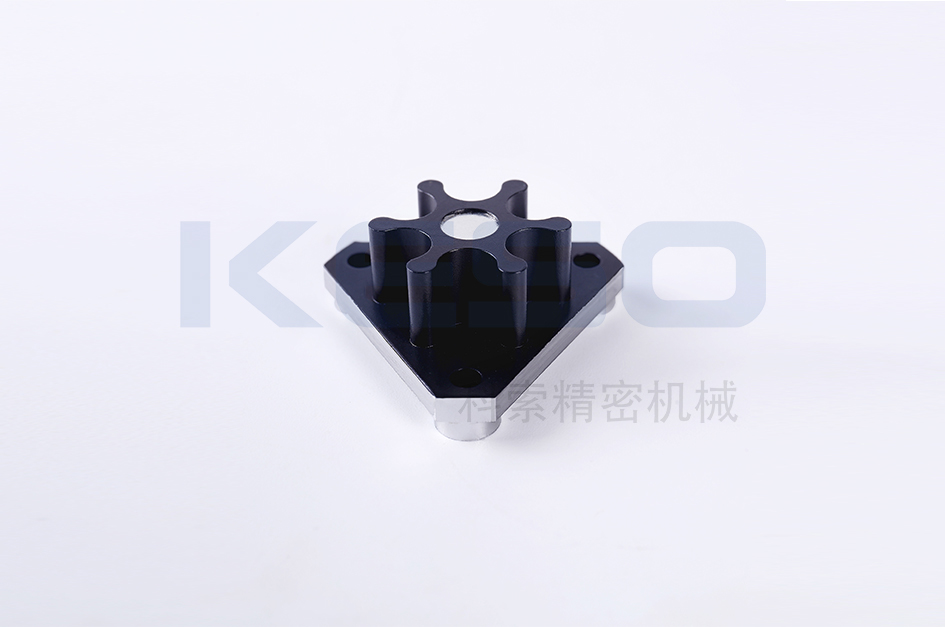

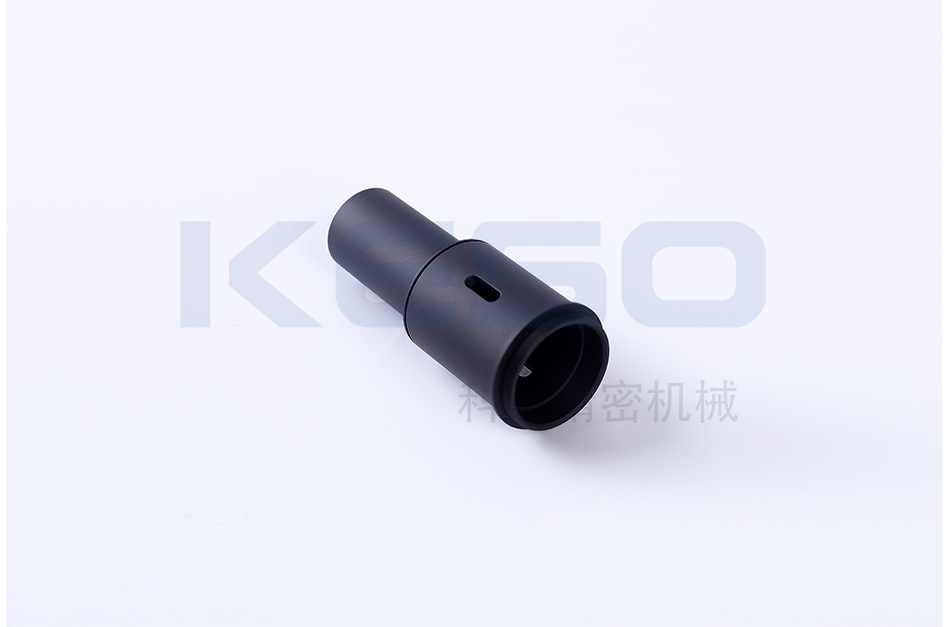

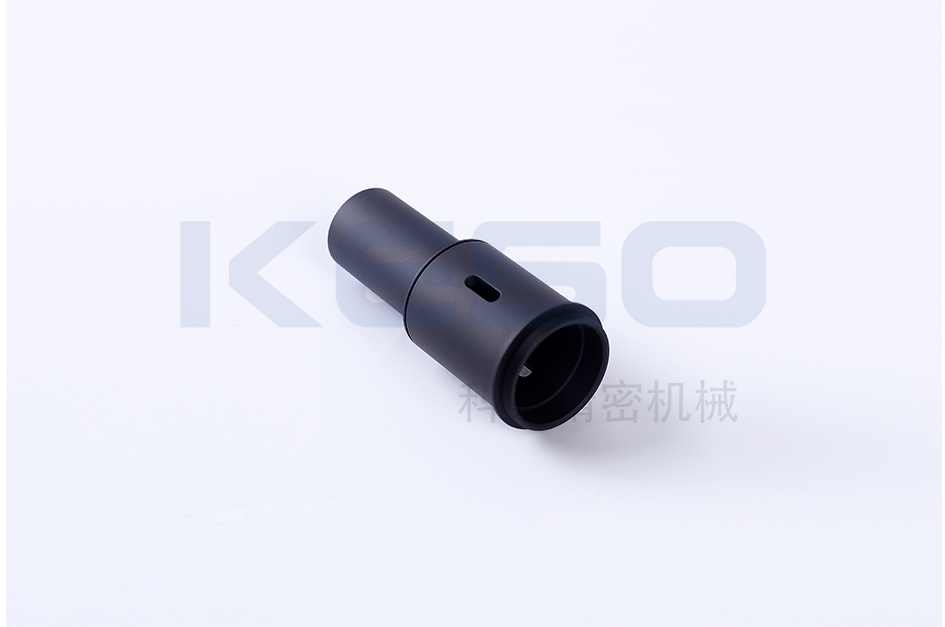

We specialize in processing structures and materials

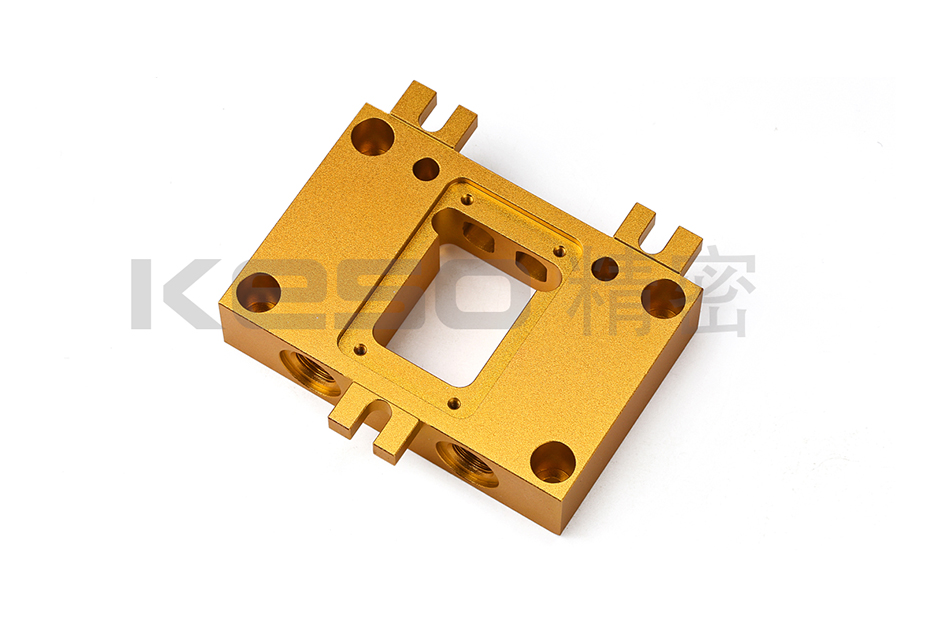

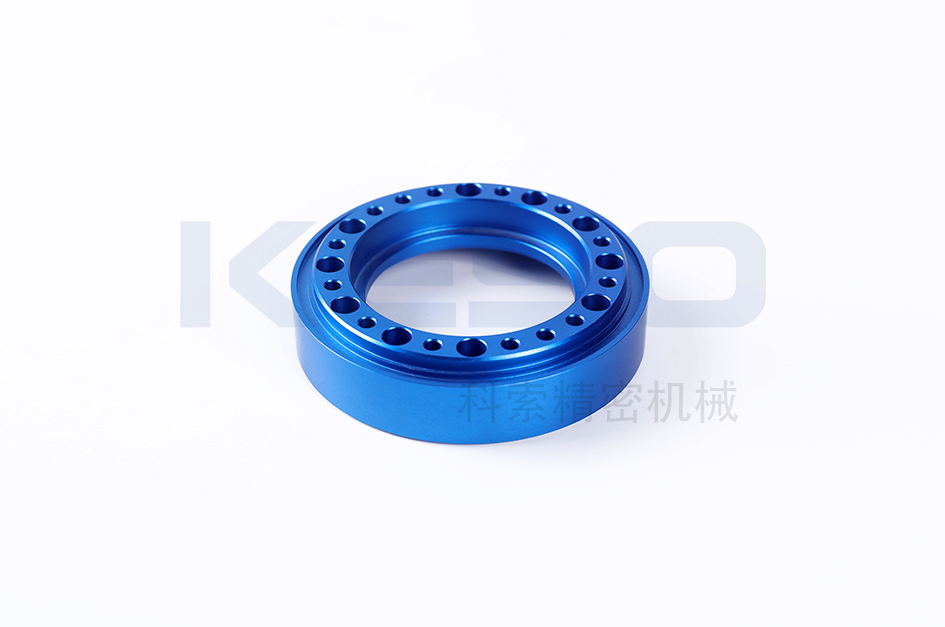

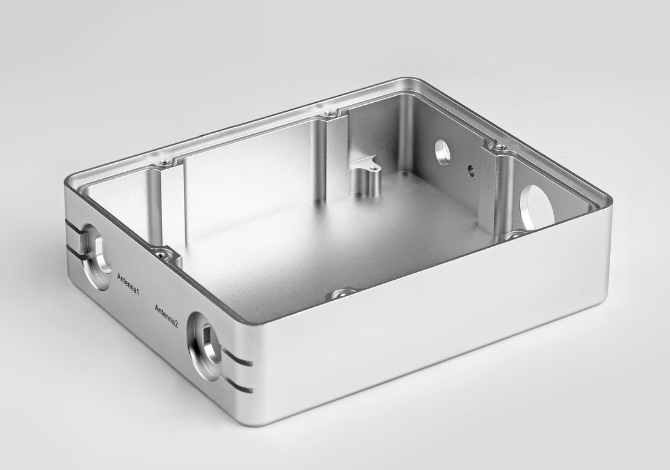

Aluminum alloy series:

Various aluminum alloys such as 7075 7A04 6061 LY12 5052 can provide stable oxidation quality

Stainless steel:

302 303 304 316 17-4 316LVM

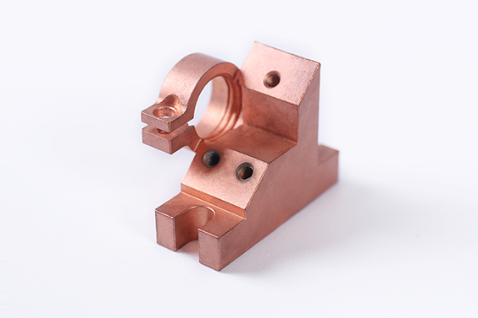

Copper raw material:

H62 H59 H69 QBe2.5 Qsn6.5 T1 T2

High performance material:

TC4 superalloy memory alloy 30CrMnSi, etc

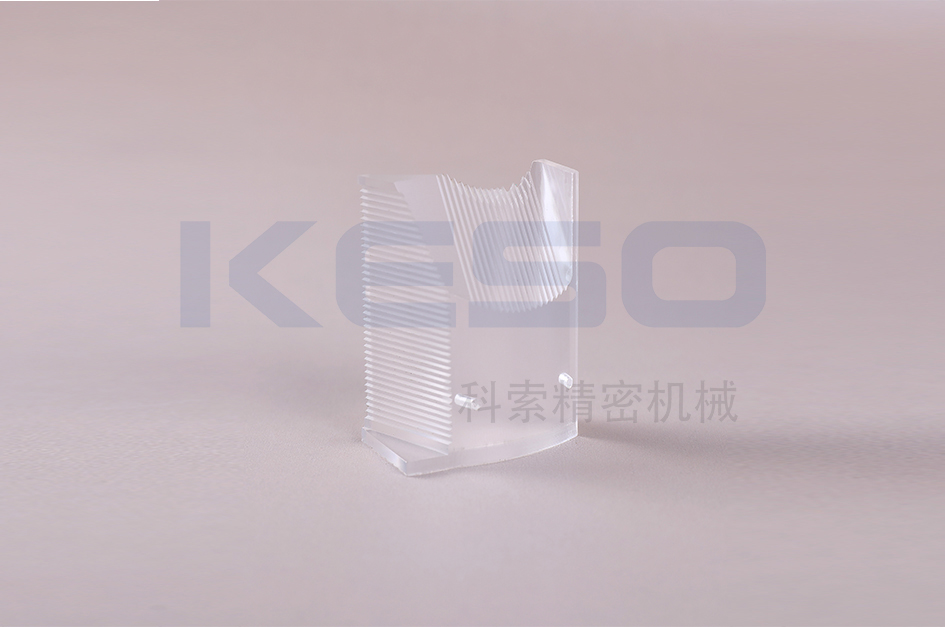

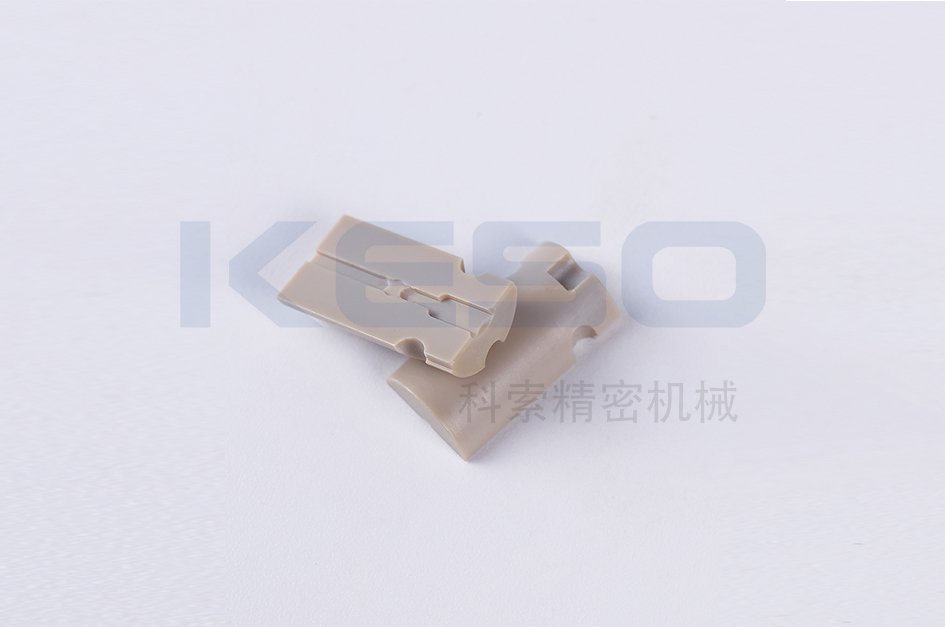

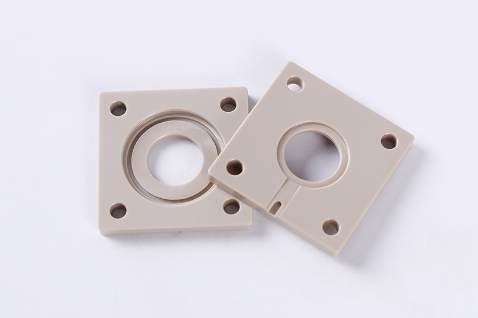

Insulating material system:

PEEK POM polytetrafluoroimide nylon

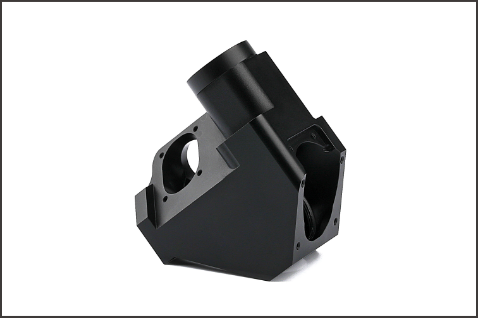

Surface treatment advantage:

Matte black oxidation Local oxidation conductive oxidation Hard copper oxide black medical passivation

We specialize in processing structures and materials

Collaborating with KESO

Our process research and development capabilities keep up with your zero risk transformation from prototype to mass production

Whether it is trial production or mass production, we have complete processing standards and feature processing specifications, and the production standards database has been accumulated for 11 years and has been continuous. Self-developed five-axis CNC automatic production unit, stable processing accuracy: 0.002mm, it can automatically load and unload materials and tools, online measurement of the processed material accuracy and tool anomaly management. With the interchangeable clamping and positioning system of KESO throughout the workshop, the positioning error caused by repeated clamping can be solved, and the production workshop can realize the conventional precision machining of 0.005mm and the high-precision machining of 0.002mm.

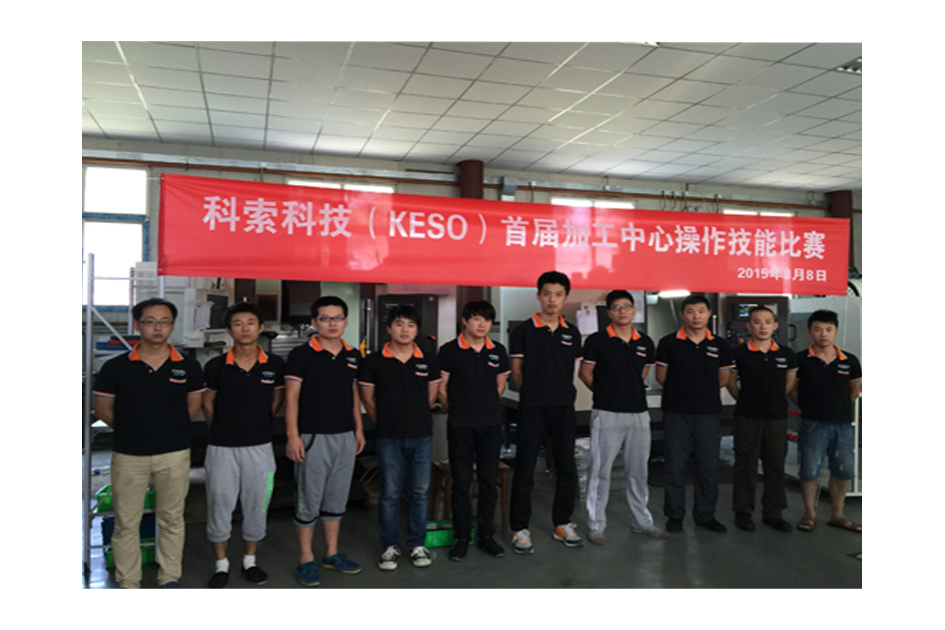

Red attire

Quality control

Black attire

Production personnel

Grey attire

Production support personnel

Precision level prototype manufacturing factory

Event display

Contact Us

Beijing Keso Precision Machinery Co., Ltd

Telephone: 010-80716348 ; 010-80741186

WeChat:Click to add WeChat

Inquiry email: sales@kesochina.com

Craft Centre: 5th Floor, South Building, Beinong Science and Technology Complex, Beiqing Road, Changping District, Beijing

Address: Building 106, Jingxi Incubation Base, Huailai County, Zhangjiakou

Understanding Capability Download Page